PCB Membrane Switch

PCB always refers to FR4 PCB. FR-4, is a widely acceptable international grade destination for fiberglass reinforced epoxy laminated that are flame retardant (self-extinguishing). After add copper layer on one or each side FR4, it become to Copper Clad Laminate (CCL), and this is the non-conductive core material for normal printed circuit board (PCB). Printed circuit board using FR4 as core material will be named as "FR4 PCB".

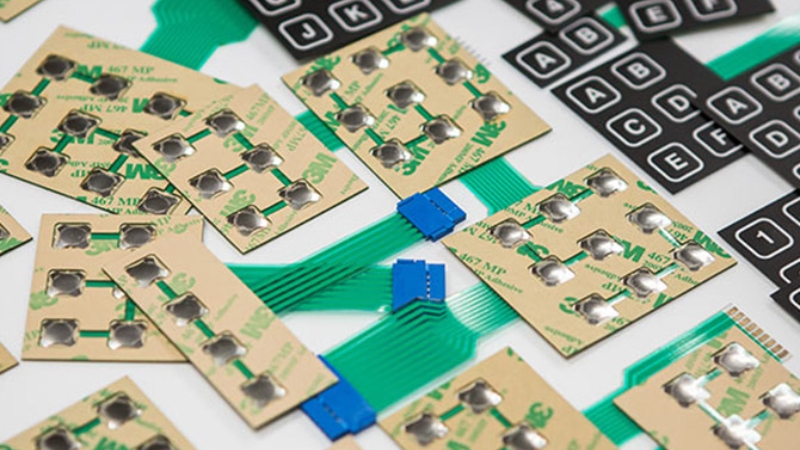

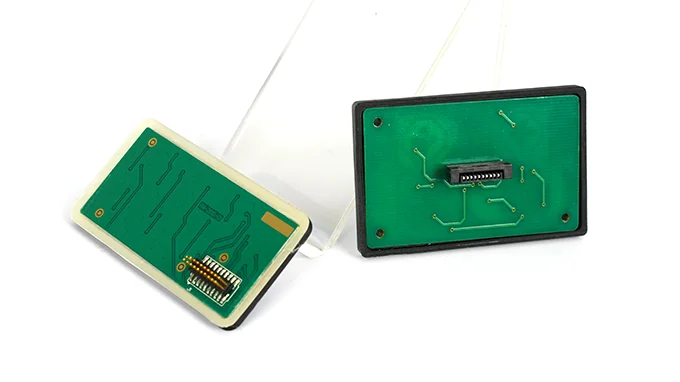

The PCB membrane switch utilizes a PCB as the main structure and support substrate, with the membrane switch on the front of the PCB, and some other components such as connectors on the backside of the PCB.

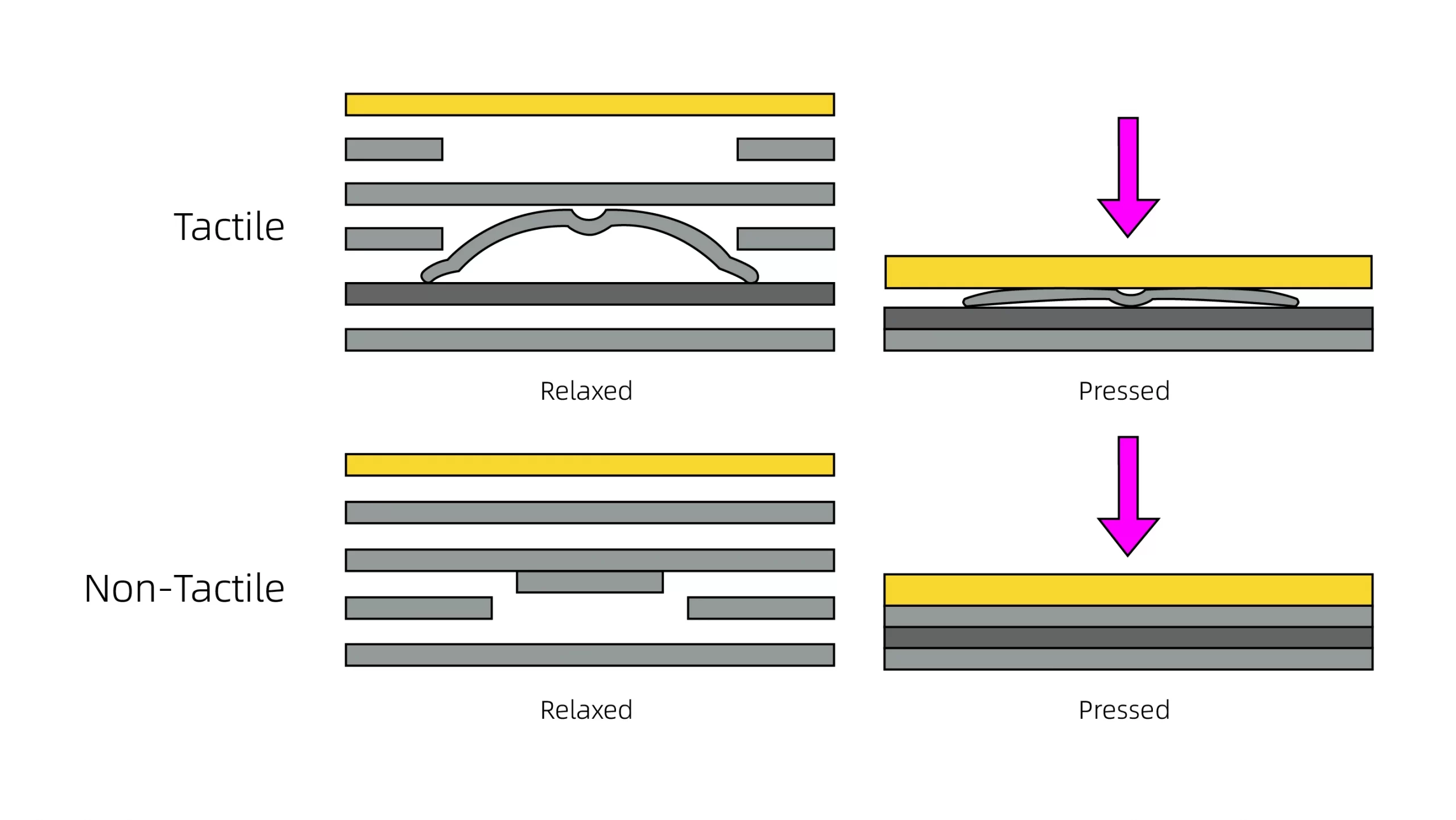

PCB membrane switch can be divided into touch membrane and non-touch membrane switch according to its tactile feel. Touch membrane switch types provide the tactile feedback to user when pressing the buttons, while non-touch membrane switches don’t provide the feedback to user, they often include audio devices and LED indicators or display changes when pressed. Non-touch membrane tactile switches are capable of up to 3,000,000 times actuations, while tactile membrane touch switches only can be achieved to 1,000,000 actuations.

There are a variety of materials that may be utilized in manufacturing membrane touch switches. These materials affect the features of the resulting membrane touch switch. For example, polyester frequently is used as the film when constructing membrane touch switches because of its durability and high temperature properties. For PCB membrane switch, it always be used for applications where requires good tactile feeling and enough support. Although the PCB membrane touch switches are more costly than PET or silver FPC switches, they still enjoy some additional features:

•High conductivity and lower electrical resistance

•Strong adhesion/fast curing

•High reliability and can be used in high vibration environments

•LED, resistor, sensors are available

•Custom waterproof, UV-proof and ESD design

•Fiber, EL, LGF backlight available

•Well-suited for smaller designs where dense circuit patterns designing, by using PTH technology to greatly utilize both sides of the PCB

•Enable to enjoy all the surface treatments such as gold plating, HASL, etc.

These membrane switch types are designed to meet the exacting standards of functionality, durability, and customization required by clients across various sectors.

•Working voltage≤50VDC, working current≤100mA

•Contact resistances are in range of 0.5 ~10Ω

•Insulation resistance ≥100MΩ (100VDC)

•Substrate pressure: 2kVDC

•Rebounce time ≤6ms

•Loop resistance ≤80Ω

•Insulation ink pressure: 100VDC

•Life cycle >1,000,000 times

•Press force: 160~450g

•Working temperature: -30℃~+50℃

•Storage temperature: -20℃~+45℃, humidity: 95%±5%

Windows for PCB Membrane Switches

For some PCB membrane touch switches, we always design a window if it combines with LED chips. The reasonable design of the LED window helps to ensure the maximum lumen and maximum refractive index. The opening window is a transparent or translucent area on the panel switch, so that the user can observe the display of the light-emitting tube or liquid crystal display behind the panel. Commonly, we have three popular windows:

What are the important design considerations for windows?

Due to the increase in printing coating, the use of Windows usually increases the cost of touch membrane switches.

Whether LCD display window is clear, no reflection or smooth window.

Whether LED window is a clear or filtered window, and this window should be reflection-free.

The display should be located behind the window and nearly window to increase clarity.

Some special window coating has anti-scratch characteristics and cost is relative higher as well.

|

|

|

|

| Cost Impact | Window Criteria | Reflection-free Design | Special Coating Demands |

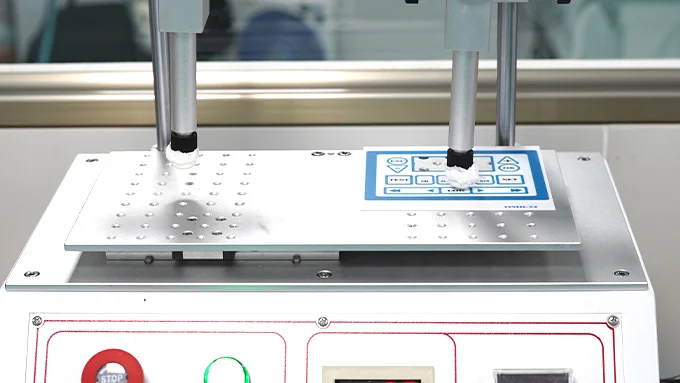

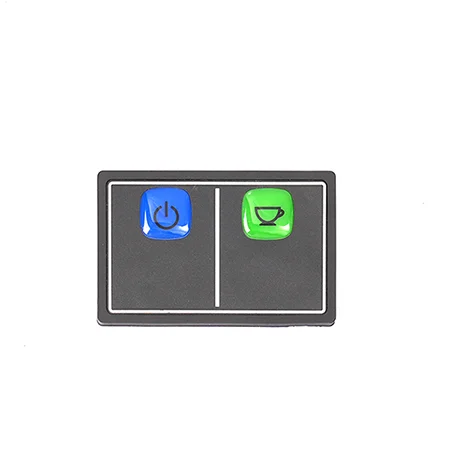

PCB Tactile Membrane Switch for Smart Car Keyboard

A membrane switch is an integrated operating system that combines key functions, indicator elements, and a control panel. It consists of four main parts: the panel, top circuit, isolation layer, and bottom circuit. When the membrane switch is pressed, the contacts on the top circuit deform downwards, making contact with the board on the bottom ...

Membrane Switch Assembled with PCB for Consumers

A membrane switch assembled with a PCB (Printed Circuit Board) serves as an advanced interface for various consumer electronics, offering a seamless combination of key functions, visual indicators, and control capabilities. Comprising essential components like the panel, top circuit, isolation layer, and bottom circuit, this integrated system delivers a responsive and durable user experience.

Latest News

Contact us online